THE TOOLS FOR ANY JOB

TOOLS FOR ANY JOB

Explore The Hive’s collection of tools and resources.

3D Printers are a maker’s best friend. 3D printers are great for prototyping and quick fixes, churning out quick parts with great attention to detail.

At the Hive, we have several Bambu Labs P1S FDM printers, three FormLabs Form 3 resin printers, one FormLabs Form 3L resin printer, one MarkForged Mark Two specialty printer, and three Stratasys F170 printers. Using these printers, you can print using PLA, ABS, TPU, PETG, standard resins, and flexible resin. With MPI or Staff approval, you can also print using Onyx, Carbon Fiber (for internal support only), and QSR dissolvable support. Whether you have a model you designed yourself or something that you found online, you can print it here! Just bring in a .STL file and we’d be glad to help. See our Wiki for more information on our available printers and materials.

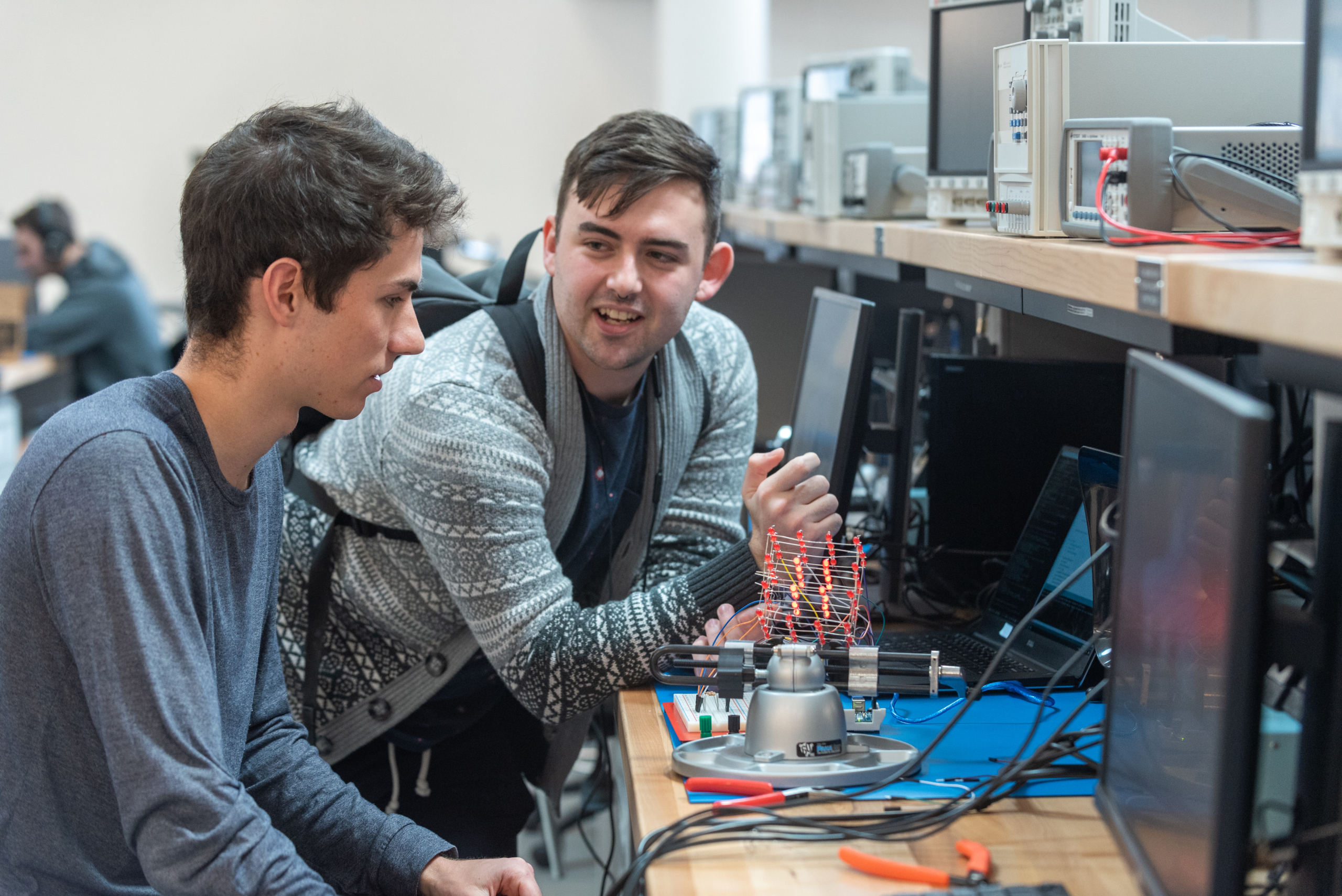

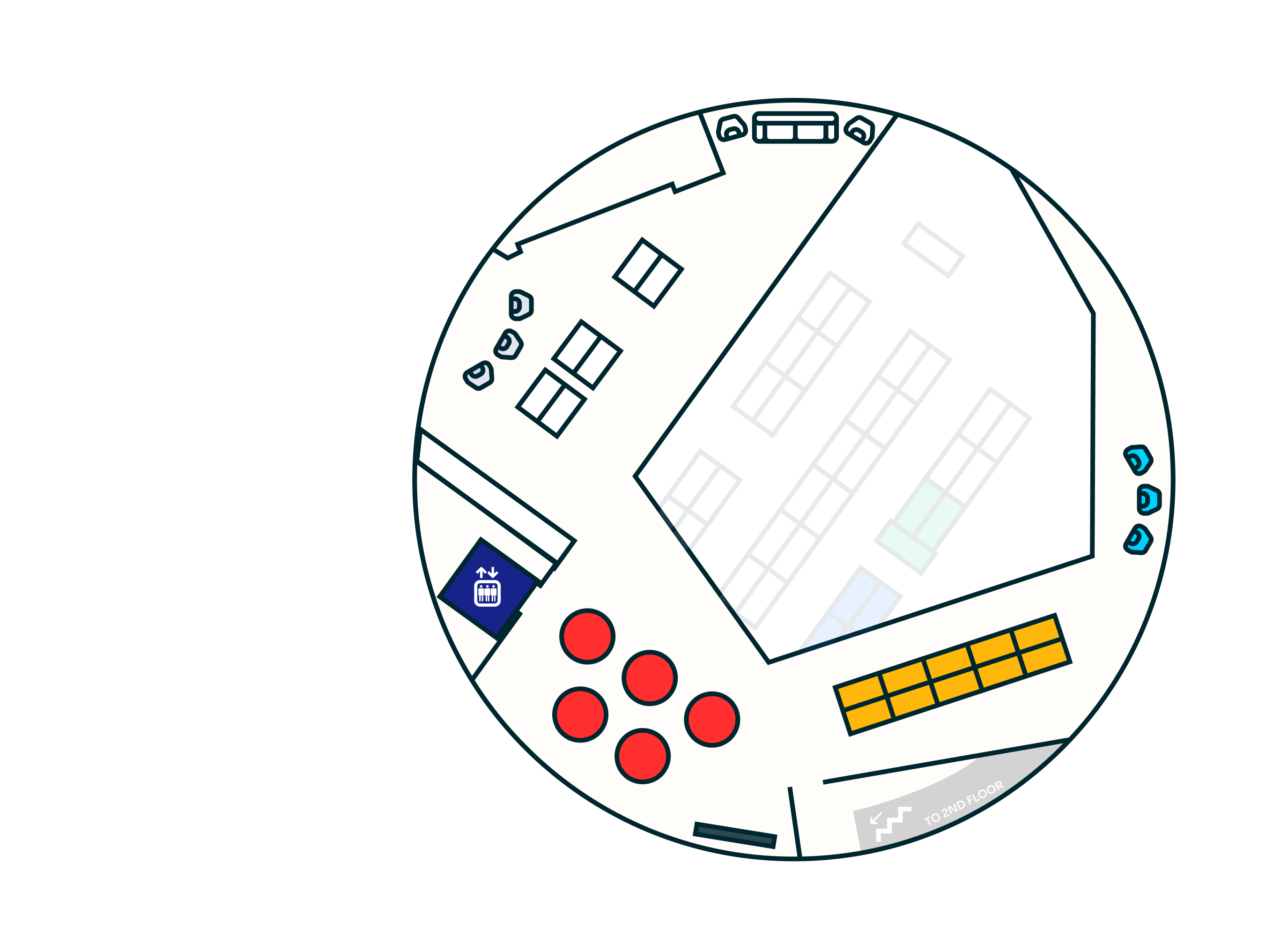

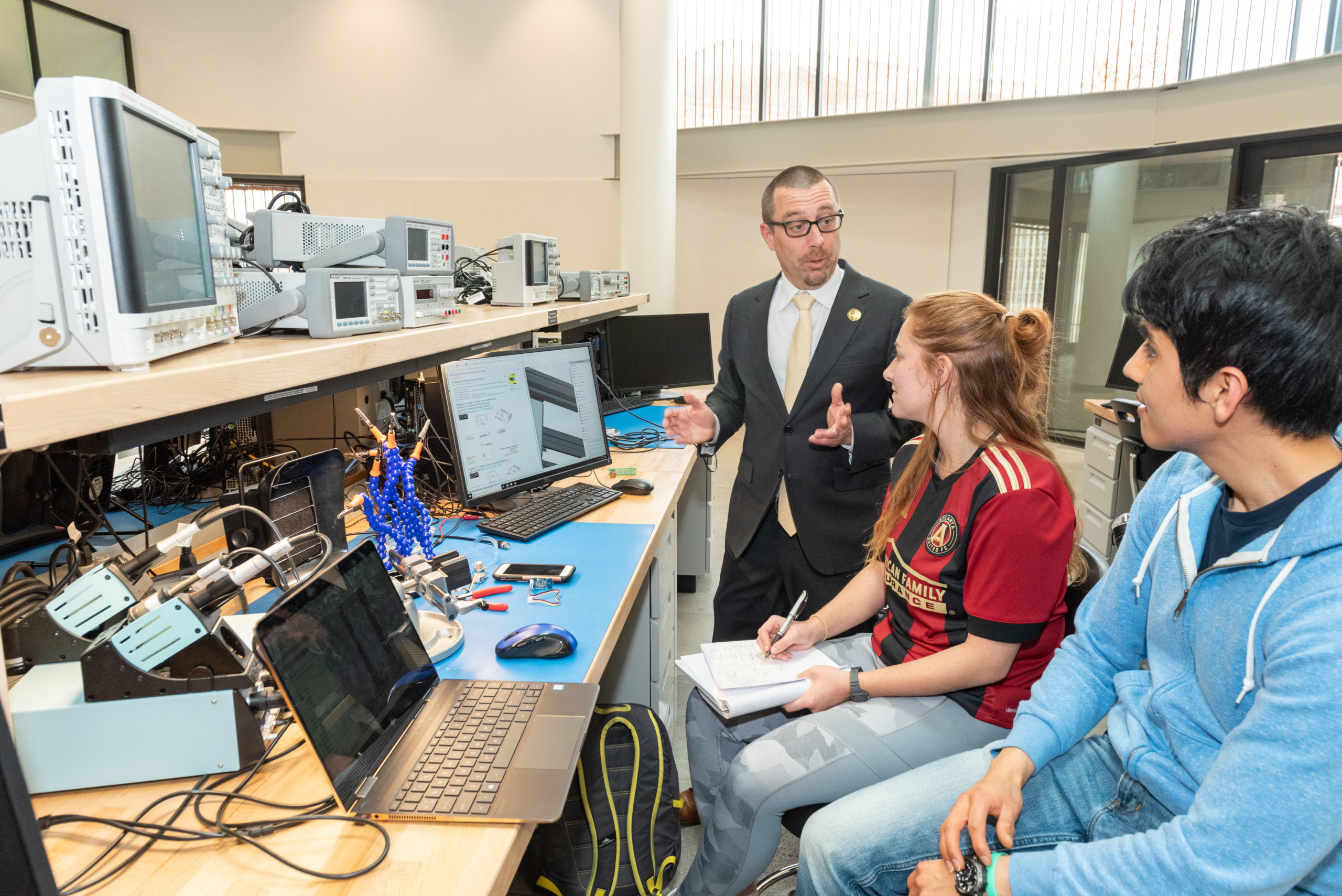

One important aspect of the Hive is our focus on electronics. As a fundamental component to any maker’s project, electronic benchtops take center stage in our space. Oscilloscopes, function generators, digital multimeters, computers, and more can be found at 24 individual benchtops. Whether you need to solder a prototype, analyze electrical signals, or troubleshoot a design, you can find it all here in the same spot. We even have more specialized tools for RF projects and surface-mount soldering.

Computers are available at each benchtop and upstairs to help you make whatever files or documentation you may need. For example, Adobe Illustrator is there to help prepare files for the laser cutters, Solidworks for modeling and exporting objects for the 3D printers, and EagleCAD to design whatever circuit you can think of.

The craft area is where you can find all the supplies for your basic crafting needs. We have cardstock, thread, heat transfer and sticky-back vinyl, rubber stamp supplies, and much more for a wide variety of creative projects. This area features two main pieces of equipment: a Brother SE1900 Sewing and Embroidery machine and a Silhouette Cameo 3.

Our Silhouette Cameo 3 can be used to make anything from custom vinyl stickers to one-of-a-kind t-shirts. The Brother SE1900 machine is great for tackling sewing projects and embroidering intricate designs.

At the Hive, we believe the front desk is an anchor for all your project needs. On your way in, stop by the front desk to sign-in and ask for help whenever you need it. Our Peer Instructors will not only help with equipment and inventory checkout, they’ll also be able to offer invaluable advice for whatever you’re doing.

Behind the front desk is our extensive component library with tools that could help you make almost any project imaginable. All components are free to use, though certain components may only be used within the space and must be returned to the front desk. With our component library, the right part for your next project is never too far away.

At the front desk, you can also check out one of our lockers (availability permitting) for two weeks at a time. Locks are provided. Please see our Rules and Policies for specific information regarding locker checkout and prohibited items.

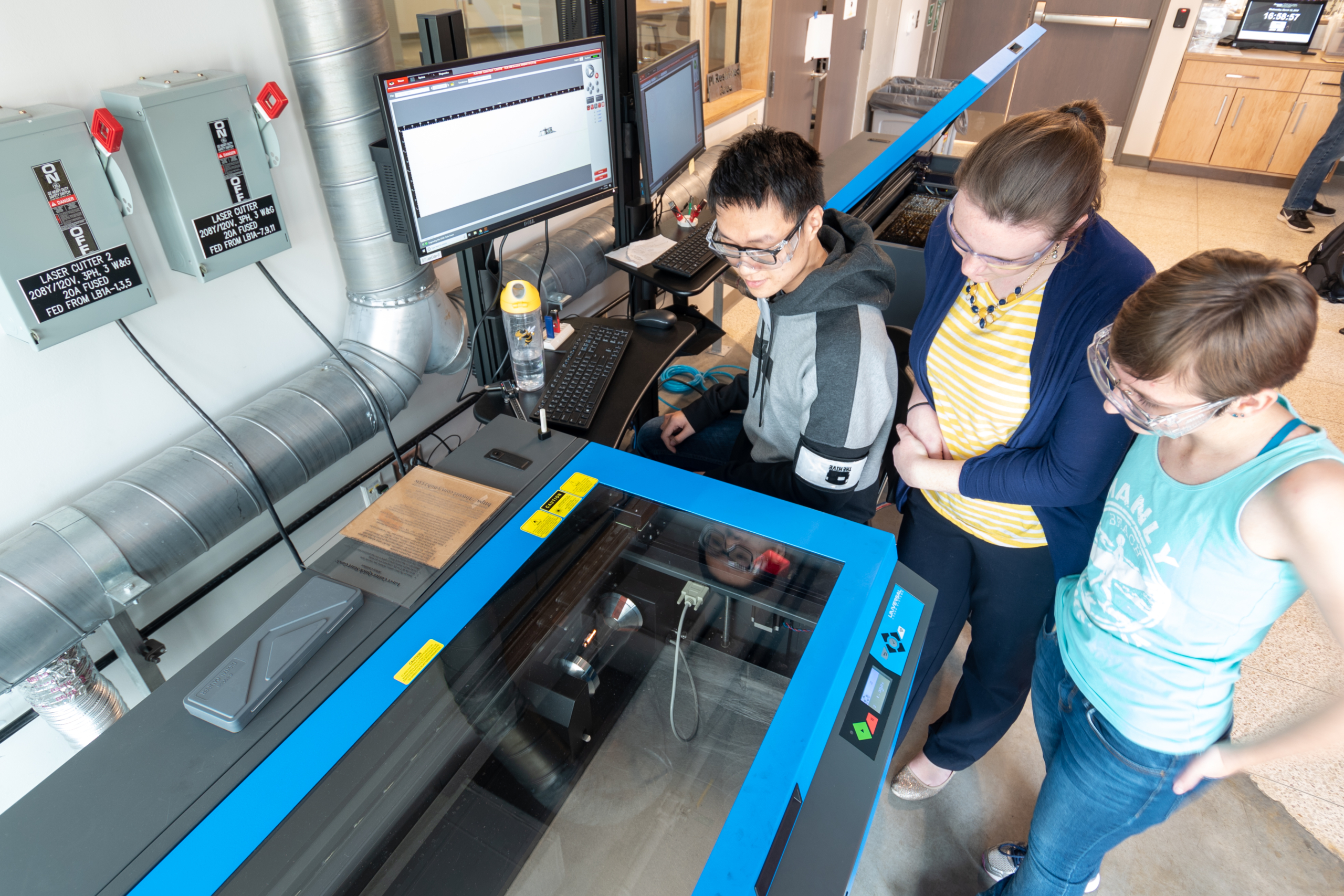

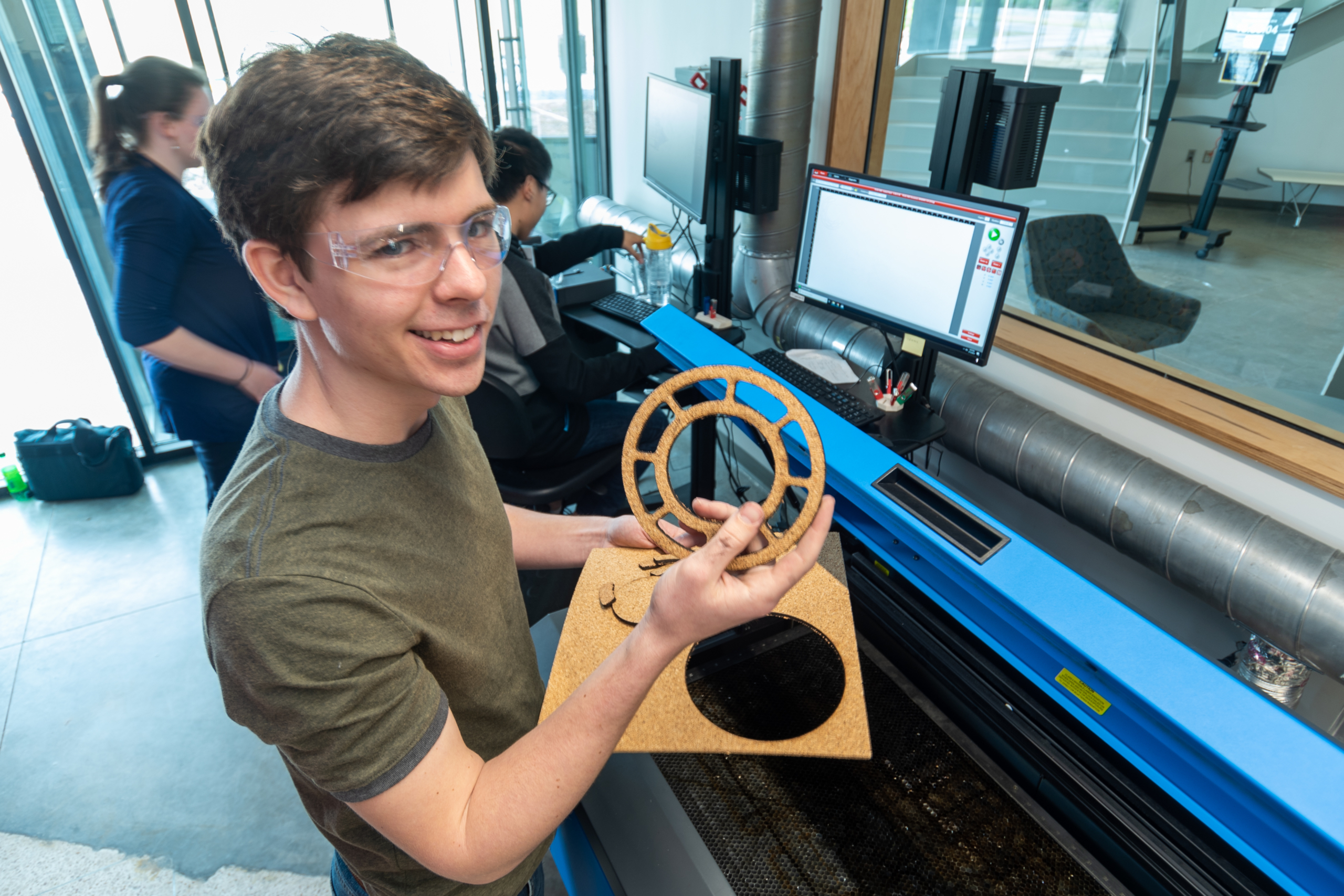

A laser cutter/engraver is one of the most versatile tools for makers and rapid prototyping. We have three laser cutters in the space: two PLS 6.150D lasers and a FabLight FL4500 fiber laser. Using the PLS lasers, materials like wood, acrylic, and single ply cardboard can be cut into intricate shapes and engraved at a high-fidelity within minutes. It can also engrave leather, metals, and glass. The fiber laser is great for cutting and engraving conductive metals, such as aluminum and stainless steel.

We recommend only cutting through materials with a maximum thickness of 1/8”, but that still leaves you with endless possibilities to explore for your projects.

No makerspace would be complete without some power tools! The machine shop has an array of tools for metalworking, woodworking and everything in between. If you need something made, there’s a good chance you’ll find the right tools in the machine shop.

You do not need to be an expert by any means. Just bring your idea and a willingness to learn, a Peer Instructor can help guide you from there.

Find a complete list of equipment on our Wiki.

Our paint booth uses a filtered ventilation system to contain fumes from the spray paints, finishes, and stains you need to finish off your project. The work surface inside is protected by a roll of craft paper that can be replaced as needed.

Cans of spray paint in different finishes and colors are located on the metal shelf in the corner. There is also a new airbrush gun to give your projects a more even finish. Working with wood? We also provide an assortment of wood stains, finishes, and lacquers you are free to use, but more specific colors or finishes may need to be purchased.

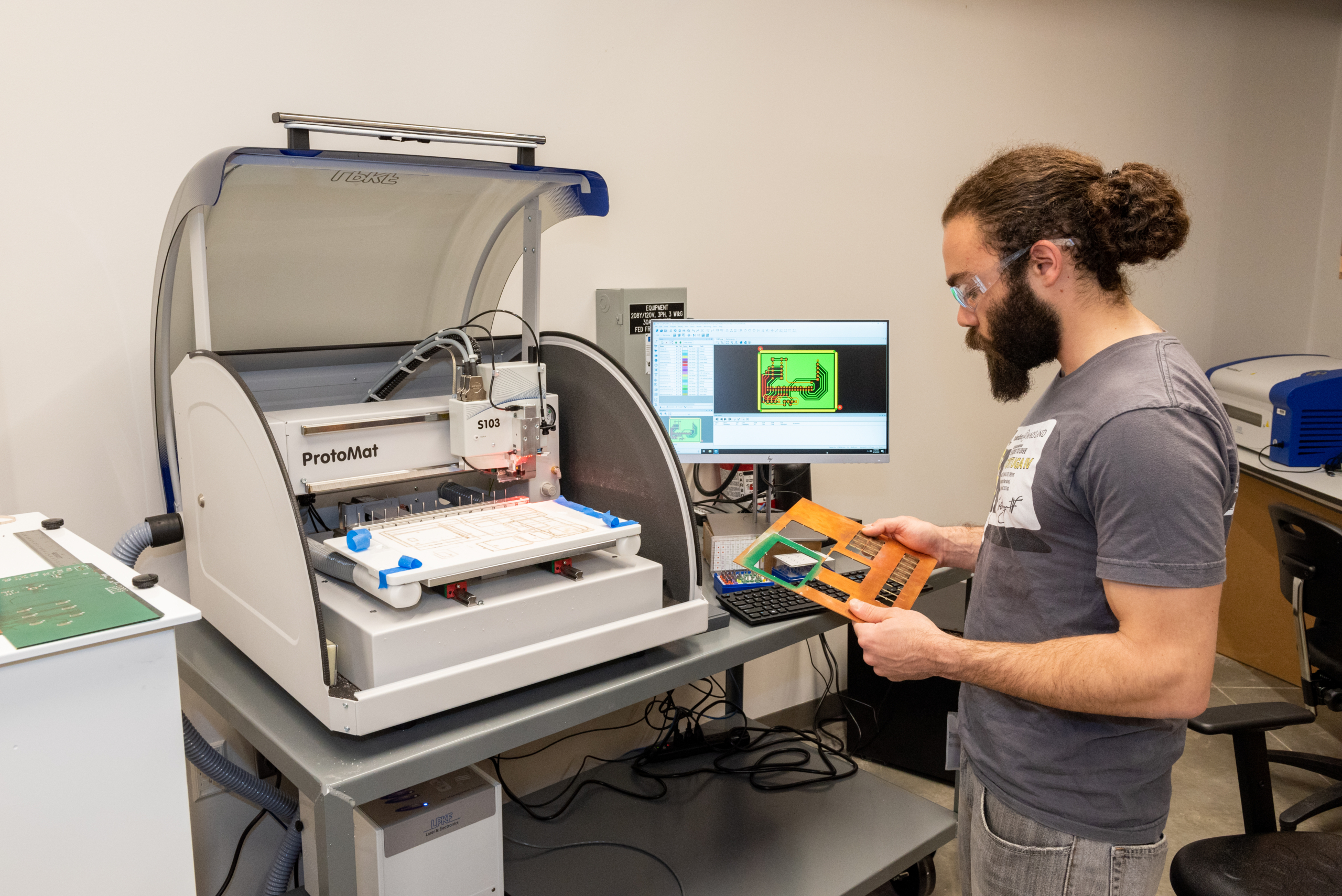

Take your projects to the next level using our suite of LPKF equipment to rapidly prototype circuits like the ones found in remote controllers, keyboards, and computers. These advanced machines give you the opportunity to quickly create and test custom circuit designs for your own projects. Training is no longer required, and our extensive manual will walk you through the entire process!

Don’t have any material to work with? No problem! Sheets of double-sided copper on FR4 in two different weights (0.5 oz/ft^2 (18 um) and 1 oz/ft^2 (35 um)) are available to use for free.

Parts Inventory

FAQs.

If you have any other questions, we’d love to hear them in-person or over email!